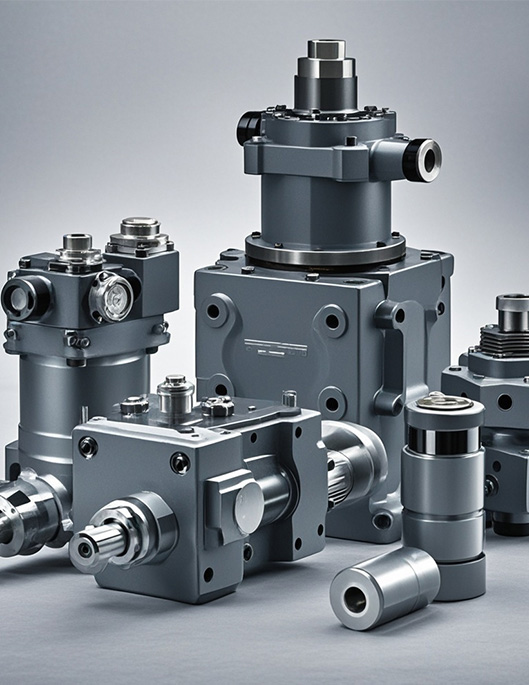

Design and Construction

The main components of a hydraulic breaker include the housing, piston, and backhead. The housing is made from high-strength steel, engineered to withstand the extreme forces and vibrations that occur during operation. The piston is a precision-crafted part that moves with great force inside the cylinder. It is designed with specific profiles and surface treatments to optimize its performance and durability. The backhead serves as the connection point to the excavator or other carrier machinery and houses important parts like the accumulator and valves.

Working Principle

It operates based on hydraulic power. High-pressure hydraulic fluid is supplied from the carrier machine’s hydraulic system. This fluid enters the breaker’s chamber, where it forces the piston to move at high speed. The piston strikes the tool bit, generating an impact force. This impact is transmitted to the work surface, such as concrete, rock, or asphalt. The repetitive impacts break up the material, making it easier to remove or process. The energy transfer is highly efficient, allowing for significant breakage power even in tough conditions.